Dec 6th 2020

Tell Tale Signs That You Need to Replace Your Leaf Springs

Tell Tale Signs That You Need to Replace Your Leaf Springs

Jump to Section:

- What are the Signs of Damaged Leaf Springs?

- Leaf Spring Replacement Options

- Can I Drive With a Broken Leaf Spring?

- What Causes a Leaf Spring to Break?

- How to Diagnose Leaf Springs

If you own a pickup truck, van or SUV, chances are good you expect a lot from your suspension. One of the key components that help you carry and tow those heavy loads day in and day out are leaf springs designed to support your vehicle's suspension system. In fact, you often don’t know exactly how important the performance of your leaf springs are until you find that they are not working correctly any longer.

Your factory-installed metal leaf springs are made to last for a general period of time before eventually wearing down and requiring replacement. If you're in tune with the way your vehicle handles and performs, you're sure to notice signs of worn-out leaf springs. This might be due to a rough ride, excess vibration when your car or truck is fully loaded and many other indicators.

No matter what tips you off that your suspension isn't doing its job, when it is time to replace your leaf springs, it is best to get it done right away. Be alert to the tell-tale signs that you need to replace your leaf springs to avoid unsafe driving conditions and keep your vehicle on the road and running strong.

How to tell if leaf springs are bad:

- Squeaky sounds while your truck is in motion

- Slouching on one side

- Sagging in the back

- Diminished handling

- Trouble hauling and towing loads

- Suspension bottoming out

- Cracks on leaves

Squeaky sounds are a sign of vehicular distress. The sound will only occur as you drive the vehicle, which can make it difficult to pinpoint the source of the problem. However, squeaky leaf springs might be the culprit.

To determine whether the squeaking is being caused by the leaf springs, park your truck on a flat piece of land and examine the front and back of the vehicle from side to side. If the truck is slouched on one side, there's probably a problem with one of the springs. Squeaking noises can also occur if the bolts are loose in one of the springs. To see whether this is the problem, jack the truck and examine the springs. Do any of the bolts feel loose? If so, the leaves might shake while the vehicle is in motion. This problem should be remedied immediately before it leads to more costly issues with your truck.

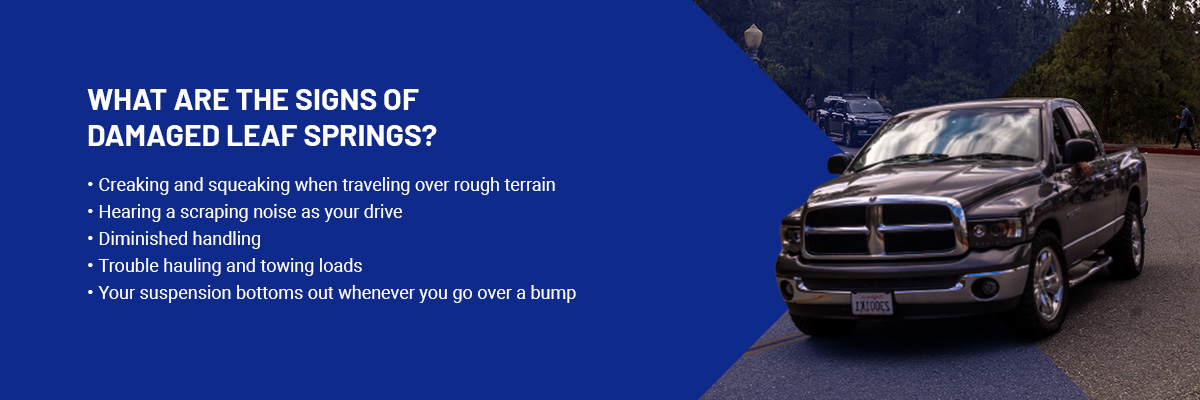

What are the Signs of Damaged Leaf Springs?

There are certain services you know you're going to need over the lifespan of a car or truck, ranging from changing fluids, batteries and tires to replacing brakes, the timing belt and the water pump. As important as they are to your vehicle's performance, the question of when to replace leaf springs is often the last thing on your mind. If you are not checking and inspecting your leaf springs regularly, then you might end up with problems that end up ruining your ride.

While further inspection is required to confirm worn-out or broken leaf springs definitively, using your senses is often enough to detect a problem. Creacking and squeaking often indicates issues with leaf springs. If you're experiencing diminished handling and trouble hauling and towing loads, or your suspension bottoms out whenever you go over a bump, you might have worn or cracked leaf springs that need an immediate replacement.

How to Tell if You Need New Leaf Springs

Even subtle clues your leaf springs are showing signs of wear and tear or failure is warning enough to take a closer look. Often, you can see if there are problems by parking on a flat surface and looking at your vehicle to see if one side sits lower than the other. If the car lies low on one side, then it’s time to remove the wheels and inspect further.

This procedure can quickly be done by an amateur mechanic using a few basic tools. However, some may also wish to bring their vehicle to a professional repair shop for a more thorough inspection. After lifting your truck and taking off the wheels, clean the leaf springs with a wire brush to remove the dirt and grime and look for wear and cracks. If any exist, then replacement leaf springs are the only logical choice.

A compromised suspension system not only diminishes your capabilities but is also potentially dangerous. If the leaf springs break completely and your axle is detached, with further use you risk extensive damage to the chassis of your car or truck. A failure of this nature can also impact the condition of a variety of other systems and components, resulting in far more costly repairs or a total loss.

Leaf Spring Replacement Options

At General Spring, we carry a range of options in replacement aftermarket leaf springs depending on your make and model as well as your applications. We offer standard options that meet or exceed the quality of OEM parts.

If your leaf springs have only lasted a short period due to heavy use and challenging jobs and work environments, you may want to talk to our experts about heavy-duty leaf springs. The standard leaf springs on a car or truck are only rated to hold a certain amount of weight, and if you are routinely carrying heavy loads, this can affect the wear on your leaf springs. Our heavy-duty options are designed to increase hauling and towing capacity and stand up to the most challenging applications.

Find out more before you just replace the springs with the factory models.

Need a Leaf Spring Replacement? Turn to General Spring

You may have many questions as it relates to finding the right leaf springs to replace those that are damaged on your vehicle, and talking to experts who work on suspensions every day can help. At General Spring, we have been an automotive leaf spring and suspension authority since 1965, and even today still operate a full-service shop in the New Century, KS area.

When you call the technicians on the floor, you’ll be speaking with the same people who build our high-quality suspension products. Our experienced representatives will be happy to answer all your questions about when to replace leaf springs and assist in identifying the products that make the most sense for you. We can also design and manufacture custom-made leaf springs for any application, including older vehicles where leaf springs are no longer readily available.

Order Your Replacement Leaf Springs Today

Don't put off inspecting your suspension or ignore the signs of broken leaf springs. General Spring offers a complete range of cost-effective solutions for fixing the problem and restoring the quality of your ride. We provide fast shipping across the country as well as an excellent one-year warranty on all of the leaf springs we sell.

Contact us using our online form for more information on the tell-tale signs your leaf springs need replacing or to request assistance placing an order. We’re confident that we can assist you with any suspension problem you may have.

Can I Drive With a Broken Leaf Spring?

Technically, you can drive a truck with a broken leaf spring, but that doesn't mean you should. You'll be able to drive your truck for a short distance, preferably to a place where you can fix the problem. Driving a truck with a broken middle leaf could render your vehicle unstable, but not too dangerous, provided you limit your driving to the nearest, safest places.

What Causes a Leaf Spring to Break?

Leaf springs are susceptible to damage because of the number of moving parts they have, as well as the wear and tear they experience throughout their lifespan. If you've discovered one of your leaf springs has broken, you may be wondering, "How long can I drive with a broken leaf spring?" The answer is that you shouldn't drive the vehicle until you have gotten the problem fixed.

That said, however, you might be able to drive the vehicle briefly in the following conditions as long as the break is not on the top leaf, which attaches the spring to the frame and thus plays a more critical role in your truck's suspension system.

- Short distances: You can make it across short distances in your truck if one of the springs has broken. For example, you could drive down your neighborhood block at 15 mph or down a gravel driveway on a farm or private estate. You can drive for periods of roughly a minute at slow speeds in areas with little or no traffic.

- Emergency trips: If one of the springs breaks, you could drive your truck from wherever you happen to discover the issue to the nearest auto repair shop. If you realize the problem in the parking lot of a supermarket or while pulled over along a city boulevard, you may be lucky if there is an auto shop within the space of a few blocks.

- Flat, familiar roads: Once you discover a broken spring, you can probably drive your truck home if the terrain is perfectly even and smooth. You might be able to drive the truck for a greater distance, especially if you go slowly and the road is mostly clear of other motorists between the place of discovery and your intended destination. If, for example, you discover a broken leaf spring on a quiet county road five miles from your house, you might be able to get your vehicle back to your house without a tow truck if you drive straight home at a slow pace.

- On your property: You could drive the truck once or twice across a short distance on your property. For example, if you need to haul a load of heavy equipment from your house to a barn some 50 feet away, a truck with a broken leaf spring will possibly get you across that distance. At the very least, you won't have to worry about an automotive breakdown in the middle of nowhere.

If all these examples seem underwhelming, the message should be clear — it is bad to drive with a broken leaf spring unless you absolutely must, and only for a short, brief distance at that. Overall, the only driving you should do with a broken spring is to a place of safety where you can park the vehicle and order a new leaf spring.

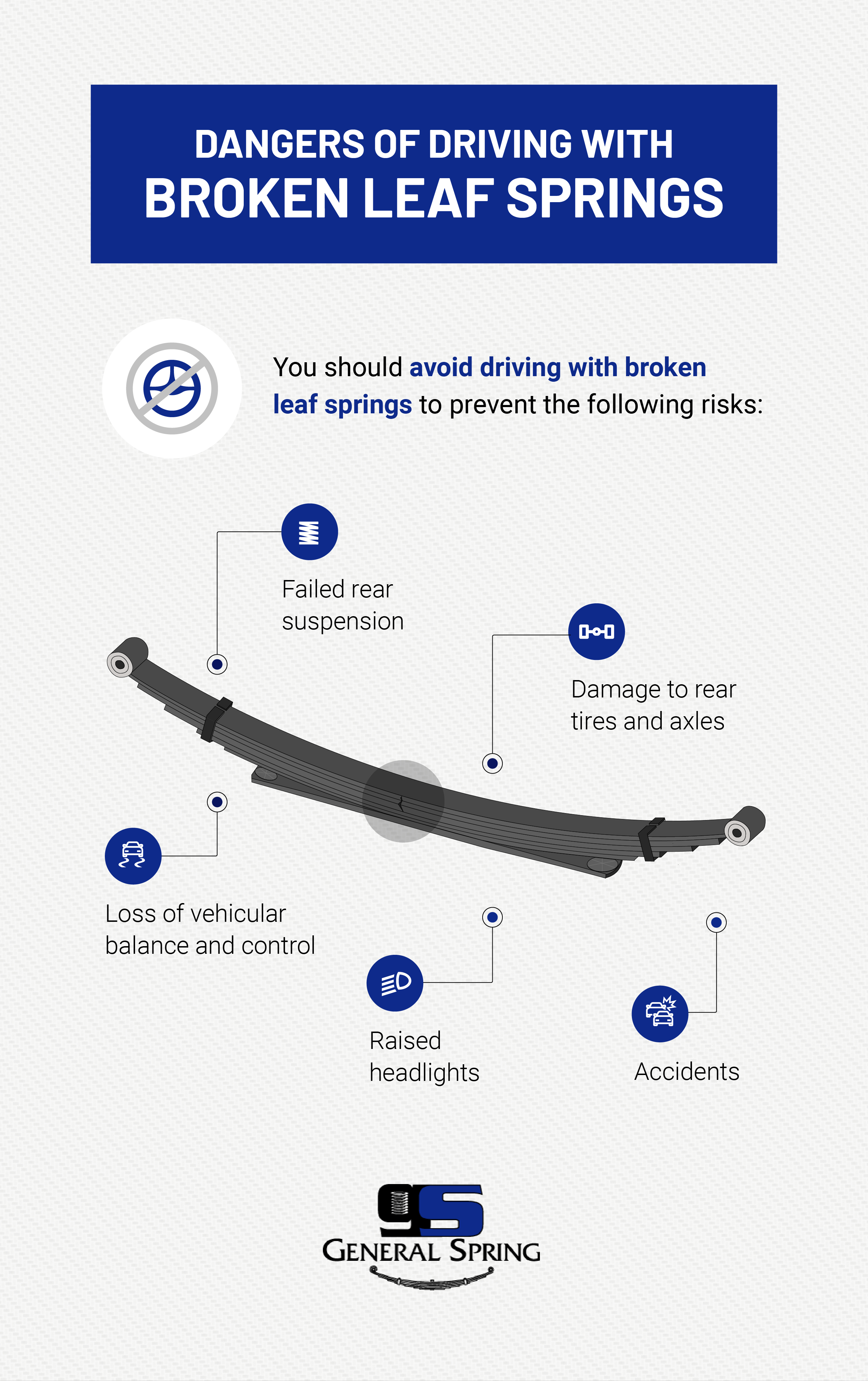

Dangers of Driving With Broken Leaf Springs

There are numerous dangers associated with damaged leaf springs. A pickup truck requires optimal suspension to drive straight when fully loaded and to keep its balance across a range of terrain. With just a single broken leaf, your vehicle could endure an imbalance of weight along one corner, and this added stress could have a hastened effect on the strength of the entire suspension system. The potential problems of a broken leaf spring run the gamut from damaged axles and worn, deflated tires to a loss of vehicle balance. At worst, a broken leaf spring could turn your truck into a roadside danger.

Failed rear suspension: Driving with a broken leaf spring bracket will inevitably place undue amounts of weight and pressure on the vehicle's rear suspension system. This situation essentially renders the vehicle a three-legged chair, placing the burden of balance on the other corners of the truck. Without a functioning suspension system, each underlying part of the truck will suffer greater stress and a reduced ability to fulfill its function. The longer you allow this condition to persist, the costlier the repairs and maintenance.

Damage to rear tires and axles: When you drive with a broken leaf spring, the most impacted parts of your truck will be the rear tires and axles. The whole purpose of your rear suspension is to handle the balance of weight that would otherwise cause your vehicle to drag in back. Without a functioning suspension, the rear weight of the vehicle could press down on the axles and cause your truck to become misaligned. Even worse, the back bumper could end up dragging along the pavement as you drive along roads and freeways. In the most severe circumstances, a bump on the road could cause the broken spring to slip off the mount and drop the fender onto the tire, which would make it practically impossible to drive the vehicle.

Loss of vehicular balance: If your truck's suspension system becomes compromised, the vehicle itself will be harder to steer, turn and control accurately. With one broken leaf, the spring on the affected side becomes less strong and stable than its counterpart on the other side of the vehicle. Consequently, the truck is liable to slouch on the affected side as you drive, especially if you drive with a heavy load. This imbalance of weight can make it incredibly difficult to drive your truck straight along a given route. The situation is most dangerous when you try to turn the vehicle, especially along narrow corners.

Raised headlights: A broken leaf spring and the effects it could have on your truck can put fellow motorists in danger. When you drive along city streets and boulevards, the slouching and swerving of your truck will undoubtedly put other drivers ill at ease. As your truck slouches at the rear, the front will rise upward, sending your headlights beaming above their intended aim. You could subject oncoming motorists to momentary light blindness and leave them unable to steer their vehicles properly.

Accidents: The most significant consequence of a broken leaf spring is the higher probability of an accident along the roadway. When you cannot properly control your vehicle, you won't be able to stop at a second's notice or swerve to safety amid an oncoming danger. Given the truck's compromised turning ability, you could easily stub a curb while making sharp turns. That could be especially dangerous on corners where trees, light poles or fire hydrants are present.

Solutions for Adding a New Leaf Spring

If you notice problems with your truck's rear suspension, perform an underside inspection for wear, cracks and damage along both of the leaf springs. With a flashlight in hand, take a close look at each of the springs. Do you notice cracks or chips in any of the leaves? These will inevitably be a source of problems in your vehicle's balance. Also, do you notice any corrosion along the leaf springs? If the leaves become heavily corroded, it could render the springs dull and inflexible. Depending on the extent of the wear or damage, you may find yourself needing to replace one leaf, two leaves, one spring or both springs.

Add an individual leaf: If one of your leaf springs has a single broken leaf, you can salvage the spring by replacing the leaf. Once you have this new leaf installed, you might find yourself surprised by the improved performance of your truck. You can also salvage a leaf spring with two broken leaves by switching our those leaves for new ones. If you discover broken leaves in both springs, it's up to you whether to replace the leaves or buy new leaf springs for your truck.

Replace one leaf spring: When you discover a broken leaf spring, you might find the opposite end of your vehicle's underside does not reflect your problems. You might have a problem where one spring has several broken leaves, while the other is solidly intact. An issue such as this can become quite noticeable if your truck slouches on the affected side as you drive with a loaded back. You might also have a situation where the affected spring becomes heavily corroded due to disproportionate exposure to rock salt and rainwater along the roadways. In any case, you might need to change out the leaf spring.

Replace both leaf springs: As you inspect your leaf springs for cracks, corrosion and general wear, you might conclude that both springs have run their course. At this point, you will need to replace your leaf springs. You might have made this discovery during a routine inspection of your vehicle's underside, in which case you may not have noticed the gradual declining performance of your vehicle. Alternately, you might experience a sharp decline in the truck's performance and perform an emergency underside inspection, only to discover advanced spring wear. In either case, you could be pleasantly surprised by the vastly improved performance of your truck once you install a new pair of rear leaf springs.

Buy bigger leaf springs: When you buy new leaf springs for your pickup truck, you might decide to trade up to a thicker, more robust pair of springs. If you place larger leaf springs under your truck, the boost to your rear suspension could take the whole driving experience to the next levels of comfort and riding performance. When you drive with full loads, the back of your vehicle will have even more of a cushiony lift, which will give you a smoother riding experience on gravelly terrains.

Benefits of Adding New Leaf Springs

One of the best ways to enhance a truck is with a new and improved suspension system. When you trade out an old or broken pair of leaf springs for a new and possibly larger set, you will instantly notice an improvement in your truck's riding performance. As you drive around in the vehicle, the cab will feel higher, comfier and more cushiony as you drive along your usual routes. Consider the following advantages of new leaf springs:

- Improved rear suspension — With a new set of leaf springs, your truck will have improved lift and be more capable of driving smoothly with a full payload. Regardless of the terrain types on your typical routes, your truck will be able to handle the bumps of the road and absorb the bluntest of shocks. Inside the cab of the vehicle, you and your passengers will be able to drive in comfort without the shakes and bumps that often accompany rides on gravelly roads, cobblestone streets and off-road terrain.

- Smoother riding — With the improved rear suspension, the weight of your vehicle will be more bearable for your rear underside assembly. When you ride with full loads and travel across rough terrains, the impacts will be less stressful on the axles and tires. The times when you do go in for vehicle maintenance will likely result in less extensive, less costly repairs because vital components that comprise the truck's underside will last longer thanks to the improved suspension.

- Enhanced comfort — Riding in a truck with improved suspension is a more comfortable experience because of the extra-cushiony lift, which absorbs shocks and smooths out the shakes and jitters of roadway bumps and irregularities.

- Longer tire life — With the improved suspension, you can expect longer life from your tires. The added lift at the rear of the vehicle means less stress on the tires. When you drive at full loads, the tires will not have to bear as much weight and pressure. Once you have installed a new and improved set of leaf springs on your vehicle, you might notice a reduce need for stops at the tire pump. Thanks to the reduced vehicular weight and stress, the tread on the tires will remain thick and full for longer periods. If you install larger leaf springs in back and coil springs in front, you could even increase the lift of your truck and go up a tire size.

- Safer vehicle — A truck with improved suspension is safer to drive, pure and simple. Once you have a fresh set of leaf springs installed under your truck, it will largely eliminate the dangers associated with broken leaf springs and poor rear suspension. When you drive with a full load, you won't have to worry about the rear bumper possibly dragging along the pavement or one of the tires popping from excess weight. As you drive along hillsides or make sharp turns, you won't experience spooky lopsidedness or an inability to keep your vehicle straight. In many ways, driving with a new set of leaf springs is like driving a brand-new truck.

Where to Buy New Leaf Springs

For more than 50 years, General Spring has offered leaf springs, coil springs, lift kits and accessories to DIY trucking enthusiasts. We sell leaves as well as leaf spring kits for a wide range of makes and models. If a leaf on one of your springs has cracked, buy a new pair of low-cost leaf springs for your truck today at General Spring!

Is it Time for New Leaf Springs? Here’s How to Diagnose Them

One thing you don’t want to do is find out that you need new leaf springs when it’s too late! If you are carrying heavy loads, chances are it’s a workload. When hauling workloads, it is important to make sure that your vehicles are regularly maintained to ensure efficient operation to avoid worrisome and even catastrophic breakdowns.

When towing heavy loads, it is important to have healthy leaf springs installed. This can sometimes be overlooked, but it is a priority that should be at the top of the ‘To-Do” list. After all, how can you operate a successful hauling/towing business, if you don’t have a properly equipped vehicle to complete the task?

For businesses that manage larger fleets of work vehicles, this is simply a matter of undergoing a routine inspection. Yet, for smaller companies and entrepreneurs, most of this type of work must be multi-tasked by one person. This might be a problem if this person is not knowledgeable in mechanics.

You don’t have to be a certified mechanic to know when it’s time to replace your leaf springs. Here are a few ways that you can diagnose whether or not your work vehicle needs new leaf springs—without paying a mechanic to tell you!

How Should Leaf Springs Look?

Leaf springs can be found on the front or rear end attached to either the bottom or top of the axle of cars, trucks, vans and SUVs. It looks like different sizes of bowed, narrow strips of steel stacked together. This part is created to absorb the gravity of an excessive amount of weight. New leaf springs will typically have a nice coating of black paint, but if your work vehicle has seen its share of labor, chances are it may be a little dirty and rusty.

Clue #1: Look for Any Cracks

You might have to get a little dirty and inspect the leaf springs yourself. If your leaf springs have cracked, broken, or missing pieces, it is highly recommended replacing them as soon as possible.

Clue #2: Swaying

If you find that the rear end of your truck is particularly bouncy and swaying whenever you hit a bump, you might need to check to see if your leaf springs are wearing out. Leaf springs are designed to absorb the energy that bumps and gravity brings, preventing such symptoms like swaying and bouncing.

Clue #3: Can the Vehicle Carry a Heavy Load?

Any easy way to find out if your truck can even take a load is to simply look at it after it is loaded or hitched. If the back of the truck sags, that means, the leaf springs are not doing its job of upholding that extra weight. Get them replaced!

Where to Find Leaf Spring Replacements

General Spring specializes in providing our customers with original equipment manufacturing (OEM) as well as coil and heavy-duty leaf spring replacements. We have been servicing the Kansas City area for over 50 years and have expanded to provide quality leaf spring replacements throughout the United States. If you’ve conducted an inspection on your work vehicle and discovered that your leaf springs need replaced, call us today at 888-829-0619 to place your order. Search our online catalog or email us now with any inquires.